A few days ago, I wrote a post regarding one of my favourite inspect and adapt tools – Root Cause Analysis (RCA). I promised there will be three (at least) parts. Dividing the content into chunks was necessary to maintain the story readable and easier to digest. So let’s dive into the second part of the RCA method description. Those who skipped the first part I advise to invest these few minutes to get a better grip on the background. So here is the Root Cause Analysis – theoretical introduction.

First question almost always asked is “Why RCA? (Do we need it? It is freakin’ expensive (…))”. Absolutely, there is a number of different, less demanding tools for inspection and adaptation. On the other hand, RCA is one of the most comprehensive, and usually reveals massive number of findings to work with.

We can call Root Cause Analysis ‘special task force’ of inspection, and below I describe how to approach it to get the most bang for the buck. This is the heavyweight tool with all of its potential.

WHY we conduct Root Cause Analysis?

Simply put: to learn from the past and improve for the future.

The BETTER than expected path

Usually when RCA comes to mind, something negative is the the line od sight. But there is possibility of using the method to find out, why something better than expected happened.

Imagine you are Product Owner, who launched new product product recently. Or marketing campaign. And it turned out, that instead of, let’s say, 30% of increased sales, there is 70% or 80% increase. Or 180%.

Great, isn’t it? Yes, of course. But… on the other hand, there must be something, probably more than one thing, that prevented us from projecting it. Is there a gap in our market research? Do we know our customers well enough? Are there features that we downplayed, but customer loved? Or we designed the marketing campaign in any particular way that it clicked?

These are the questions to be answered. Especially if it impacted the production, supply chain, sales or customer support. Or all of these together.

The WORSE than expected path

Well, this is usual way how you encounter Root Cause Analysis. You expected more sales than you got after marketing campaign. A month before release it surfaced, that there is at least two months work remaining and release was postponed. Or your company’s carefully planned release turned into nightmare, and customers are furious. New feature development took 18+ months instead of projected 2-3. Or the supplier delivered something completely different than expected and there is a lot of rework needed.

Up to the heaviest cases. Airline pilot deliberately crashed the plane into the slope of the mountain. Or the space shuttle exploded or satellite vanished in Mars atmosphere (remember this one, there will be more about it next time, so no link 😉 ). And so on, and so on.

In other words, we experienced a (massive) pitfall, and we want to inspect the root causes and eliminate them. First step is understanding the structure of the problem.

“You can never make the same mistake twice because the second time you make it, it’s not a mistake, it’s a choice“

Stephen Denn

Root Cause Analysis Problem Structure – 3 key elements

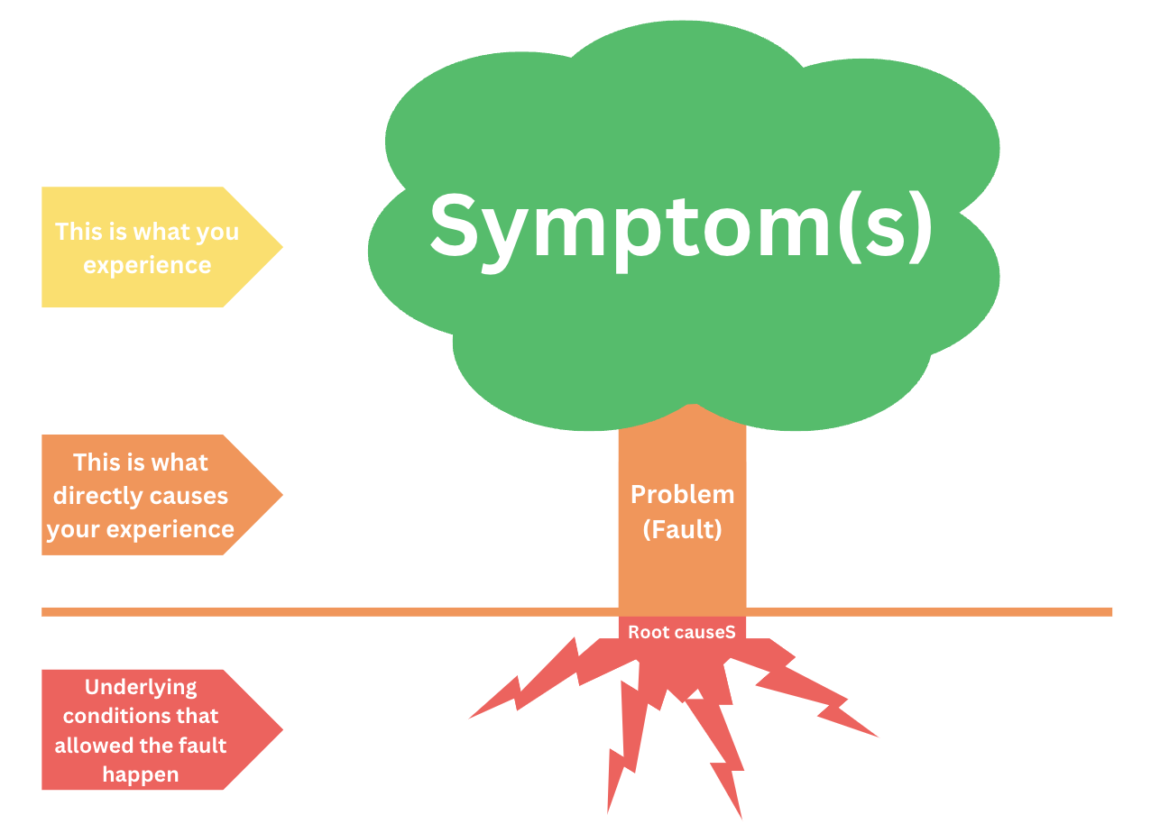

- The Symptoms

This is what you experience directly – slow performance or crashes of the app, necessity of postponing a release, social media crisis, accidents, etc. - The Problem

This is the reason directly causes above mentioned experiences. Fault present in a software. Lack of use case unnoticed. Lower than required quality of the crucial plane component. Different units used in calculations by two cooperation companies, etc. - The Root Causes

These are the underlying conditions that allowed the fault to happen in the first place. Why the problem had a chance to emerge. And why it was not noticed earlier.

Ericsson RCA – as the baseline

In often-mentioned Ericsson, the so-called “Ericsson RCA” contains two separate. The “technical” part, and the “organizational” part. Symptoms are usually clear, but often finding the problem causing those symptoms is demanding. After identifying the Problem, the second, more influential part follows, which look into the processes, procedures, practices.

Root Cause Analysis Process

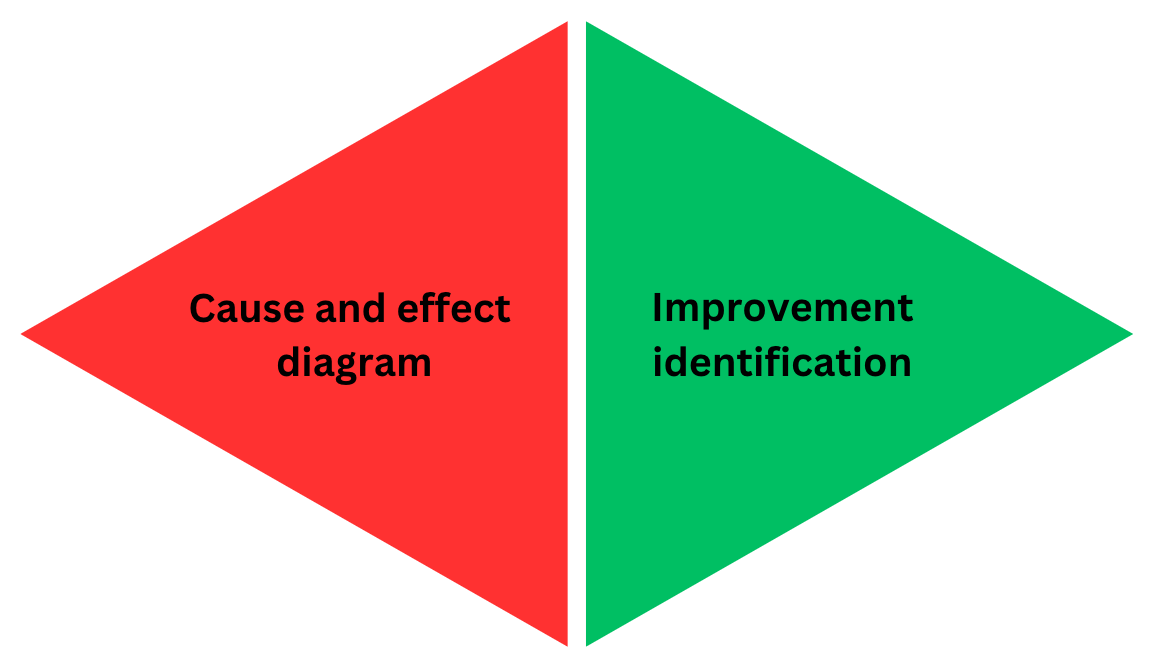

Each RCA contains two main parts, equally important. We can imagine it as a diamond created from two identical triangles. From the left hand side, where the Problem is, we build a Cause and effect diagram (I’ll describe it in following parts) searching for the Root Causes. Then, addressing the Root Causes found – we create and implement Improvement Ideas. Sometimes one improvement can fix majority of Root Causes. Sometimes it is 1 to 1. The goal is to mend all the holes, so the similar issue will not happen again.

Creating improvement ideas without proper understanding of the whole aspects of the situation is tricky. In best case, you might luckily (but to be honest – blindly) hit some Root Causes. In worst case – you might miss entirely. That means serious waste of resources and opportunity without any gain.

On the other hand, analyzing situation without making proper adjustments is pure waste. You spend time and put a lot of effort with no intention of changing situation, brrr.

It’s like Scrum – simple, but not easy.

Me 🙂

Summary of this part

This is the time for me to hit the pause button, and let it settle before we move forward with the RCA journey.

I explained the reasons for conducting the RCAs, described two legs of RCA – the positive and negative surprises.

After the review, my editor (wife :)), gave me some valuable feedback (“great, but waaaaaay too long”) 😉 I decided to divide this theoretical part into smaller chunks. Root Cause Analysis is very dense topic, so let’s use the iterative approach 🙂

Maybe there is something unclear? Maybe there is something I should expand? Or you have some questions at this point? Either way do not hesitate to contact me, I will gladly address them all.

Stay tuned for the rest,

Marcin

1 comment